Don't miss our holiday offer - 20% OFF!

For more than 30 years of history

HEBEI QIANGYU HARDWARE & MESH CO., LTD.

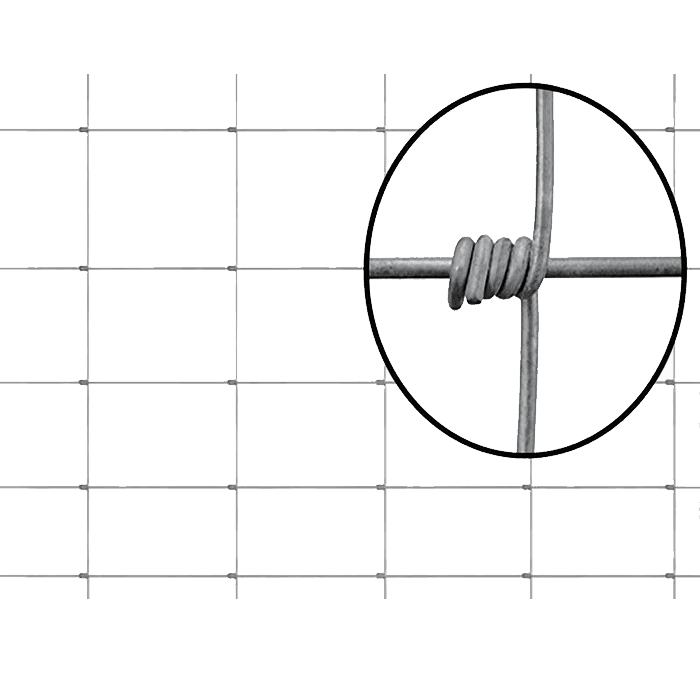

Hebei Qiangyu Hardware & Mesh Co., Ltd. is a professional manufacturer with more than thirty years of experience in fence production. We have professional sales team and design team, which can provide you with the best quality products and services.

We produce fencing equipment with a variety of equipment such as mesh welding machine, laser cutting machine, laser welding frame machine, medium welding welding machine and spraying equipment to ensure the high quality and excellent performance of our products.

Wire Mesh Fences

QIANGYU PRODUCTS

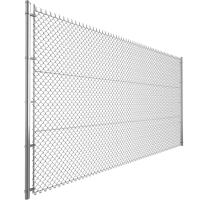

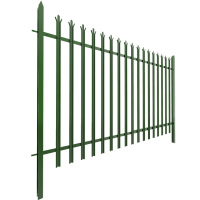

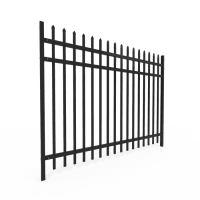

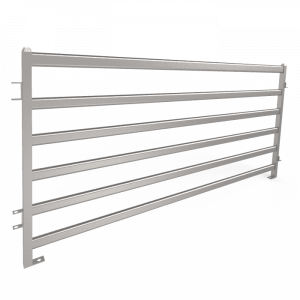

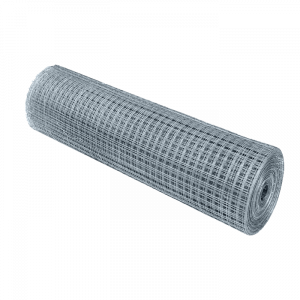

WIRE MESH FENCE

Hundreds of Wire Mesh Fences in Different Materials, Surface Treatments and Sizes.

WIRE MESH FENCE APPLICATION

QIANGYU PRODUCTS

WIRE MESH FENCE

Covers Residential, Commercial, Industrial and Martial Applications

Why Choose Us?

- Direct factory and trading company for all steel gratings.

- More than 30 years of manufacturing experience.

- ISO certificated enterprise and lots of projects endorsement.

- Strict Quality Control System Say No to defects.

- Large stocks for standard and popular sizes for fast delivery.

- Special discount for large orders and projects.

- Free sample test and customization service satisfy all your needs.

Advantages of Fence Moine

- High strength, high bearing capacity and high resistance to stress.

- Grating structure with the good drainage function, do not accumulate rain, snow, dust and debris.

- Ventilation, lighting and heat dissipation.

- Explosion protection, also can add anti-skid serrations to improve anti-skid ability.

- Anti-corrosion, anti-rust, durable.

- Simple and beautiful appearance.

- Light weight, easy to install and remove.

FAQ

If these questions do not help you, just feel free to contact our sales, we will give you satisfied solutions

A: It depends on specific order. We are always trying to meet customers’ need on delivery time.we aim to complete most of the deliveries within 15 days while some order may be offered as 30 days.

A: We have passed ISO 9001:2015 certification. Every production process are been inspected by professional QC staffs to ensure quality. Our products are well qualified as per the major international standard, like ISO, ASTM, BS/DN, etc.

A: Yes, A piece of sample is free. If you need sample, please advise us your express account and address in details. In special occasion, tooling/molding fees are at customers’ expense.

A: Our sea port is Tianjin/Xingang Port. It’s about 200 km far away from our factory.

Contact Us

Our sales representatives are ready to serve you with professional suggestions

and accurate prices

Factory Add: Room 701, Block B, Xinke International Plaza, Huai’an East Road, Yuhua District, Shijiazhuang City, Hebei Province, China

Mob: +86-18631807666 (WeChat) / +86-18931847300

Whatsapp: +8617333996886

Fax: 03187530018

E-mail: [email protected]